It will help people interested in it to get an in-site in this topic and understand it with ease

So, before we start with the topic

Let’s first understand some important terms in this paper

IMPORTANT TERMINOLOGIES

Let’s understand

Piezoelectric ceramic materials

Lead zirconate titanate (PZT), barium titanate (BT), and strontium titanate (ST) are the most widely used piezoelectric ceramic materials. where ε is the relative permittivity or dielectric constant of piezoelectric ceramic materials and is defined as the dielectric displacement per unit electric field.

What is an Acoustic

Transducer?

An acoustic transducer is an electrical device that converts sound wave vibrations into mechanical or electrical energy.

As many of you must’ve guessed

Piezoelectric ceramics are used to make modern acoustic transducers.

Here we discuss the Effect of Temperature and Pressure on the Thickness Mode Resonant Spectra of Piezoelectric Ceramic

Thickness mode : the standing wave patterns produced are called

"modes". When a piezoelectric material is excited by an ac signal two series of resonance are observed. One is in radial mode and other is in thickness mode. The frequency in thickness mode(axial) has high resonance because piezoelectric material is designed to be driven in that direction.

Resonant spectra are emission spectrums resulting from the illumination of

a substance by radiation of a definite frequency or definite frequencies.

(And of course, resonance is a phenomenon when the matching vibrations of another object increase the amplitude of an object's oscillations)

The most commonly used piezoelectric material is PZT (Lead zirconate titanate)This is the structure of PZT for

reference

Now that some of the

important terms used in a research paper are discussed with an understanding of

what the paper discusses

THEORY

Here we use the Van Dyke circuit

model that’s recommended by the IEEE standard on piezoelectricity.

Now let’s understand The van Dyke first

The branch L1 , R1 , C1 represents the mechanical behaviour of the piezoelectric disc while C0 represents the electric nature.

For the above equivalent circuit

The resonant frequency (fr)

The anti-resonant frequency(fa)

And the C1 is represented by

The

characterization of piezoelectric ceramics is done using the resonance method

as mentioned in the IEEE standard on piezoelectricity. A small ac electrical

signal is used to excite an elastic wave in the piezoelectric via an

electromechanical coupling. Depending on the sample dimensions, the frequency

at which resonance occurs is observed by measuring the impedance of the

sample at various frequencies.

EXPERIMENTAL ARRANGEMENTS

The discs used here had dimensions

of, a diameter of 25 mm, a thickness of 2 mm, and a diameter to thickness ratio

of 12.5.

And as we know scientific

experiments are a little extravagant, the flat surfaces used in the sample are

coated with silver electrodes to facilitate an ohmic contact for measuring

electric properties

What is ohmic contact? just think about this for a little while the

answer is in the name itself Ohmic contact is a low resistance junction

(non-rectifying) that provides current conduction from metal to semiconductor

and vice versa. The current here increases /decreases linearly Theoretically!!!

Let’s have a look at

the experiment and understand the context of the paper through the experiment

conducted for the paper

First Resonant and anti-resonant frequencies are observed

at different temperatures with sufficient soaking, this process is repeated 10

times and then average values are computed, and average values are calculated to

eliminate errors.

For open channel flow metering, the

transducer is located at a maximum of 10m below the water surface. The head

pressure acting on the transducer affects its resonant frequency. A height of

10 m of water creates a head pressure of approximate 1 kg.cm^2.

Weights calibrated in terms of pressure were used for

simulating the head pressure acting on the transducers, and the weight to be

applied on the disc was calibrated using the maximum pressure and the area of

the disc.

The pre-calibrated weights are

applied to the piezoelectric disc and the values of resonant and anti-resonant

frequencies are observed using the circuit shown in the fig above.

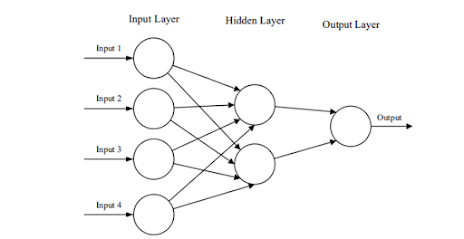

Based on these practically obtained model parameters,

mathematical modelling using an equivalent circuit approach was implemented in

Simulink.

Check what’s Simulink after reading this blog

Below fig is what Simulink does i.e., make a relevant

equivalent circuit of the piezoelectric element.

The resonant frequency is inversely proportional to the

thickness of the piezoelectric disc. As pressure is applied to the

piezoelectric element, the thickness decreases and so there is an increase in

the resonant frequency. As the pressure acting on the piezoelectric disc

increases, the stiffness increases and so the resonant frequency increases. The

values of resonant and anti-resonance frequencies obtained from the model

response match with those obtained experimentally.

CONCLUSION

In this paper, a process condition-based equivalent circuit

model of the piezoelectric disk is developed. The process conditions and their

ranges considered are suitable for underwater applications. Here the required

data is experimentally obtained and the model parameters were computed and a

more realistic model was obtained.

NOTE:-This blog is meant for Educational Purpose only .We do not own any Copyrights related to images and information , all the rights goes to their respective owners . The sole purpose of this blog is to Educate, Inspire, Empower and to create awareness in the viewers. The usage is non-commercial(Not For Profit) and we do not make any money from it.

Write your Feedback here:

https://forms.gle/C3ybXMPPUaJBgP618

FOLLOW US ON:-

INSTAGRAM :

https://bit.ly/coep_blogs_insta

LINKEDIN:

https://bit.ly/coep_blogs_linkedIn

YOUTUBE:-

https://bit.ly/Coep_blogs_YouTube